Pump & Sprayer & Lid Product Page Introduction

In modern packaging and diverse fields such as daily chemicals, gardening, and household cleaning, Pump, Sprayer, and Lid have long transcended their roles as basic sealing and dispensing tools. They have become core components that enhance product user experience, ensure the safety of contents, and convey a brand’s professional image. Whether it is the pump for essence in skincare products, the sprayer for kitchen cleaners, or the sealing lid for food cans, Pump & Sprayer & Lid work together or independently to play a crucial role in every usage scenario. The Pump ensures quantitative dispensing of liquids and prevents contamination; the Sprayer enables uniform atomized spraying to improve efficiency; the Lid protects the contents from external moisture, dust, and microorganisms while preventing leakage.

Nowadays, with the upgrading of consumers’ demands for convenience, safety, and environmental protection, as well as the industry’s higher requirements for packaging compliance and functionality, high-quality Pump & Sprayer & Lid products have become an important breakthrough for brands to achieve differentiated competition. Our Pump & Sprayer & Lid product series is developed based on in-depth insights into usage scenarios across multiple fields. By integrating innovative technologies and precision craftsmanship, we have created solutions covering industries such as daily chemicals, cosmetics, home care, gardening, food, and industry. From material selection to structural design, from functional adaptation to appearance customization, we fully meet the diverse needs of different customers for Pump & Sprayer & Lid. Every Pump & Sprayer & Lid can accurately match product characteristics, bringing users a convenient, safe, and efficient experience, while endowing brands with stronger market competitiveness.

1. Core Advantages of Pump & Sprayer & Lid Products

1.1 Excellent Sealing Performance to Protect Content Safety

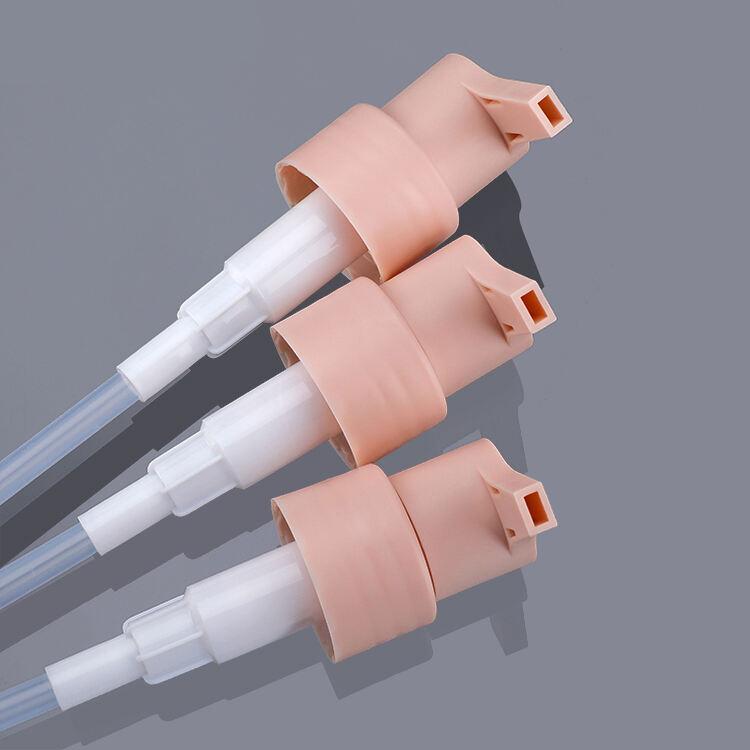

Sealing performance is a core performance indicator of Lid, Pump, and Sprayer products, and it is also the key to ensuring the quality of contents. Our Lid products adopt dual-standard materials that meet both food-grade and industrial-grade requirements, paired with precision sealing structure design. They are equipped with built-in silicone sealing rings and spiral engagement patterns that fit closely with the container mouth. Whether used for food cans (such as honey jars and nut cans) or chemical reagent bottles, they can effectively isolate air, moisture, and dust, preventing the contents from oxidizing and deteriorating, getting damp and caking, or being contaminated by microorganisms. For Pump and Sprayer products, multi-layer sealing components are installed at the connection between the pump body and the spray head to avoid liquid leakage during storage and use. Even for corrosive cleaning liquids or high-concentration skincare essences, they can be safely stored and dispensed through our Pump & Sprayer, safeguarding the stability and safety of the contents from the source.

1.2 Precise Volume Control and Uniform Atomization to Improve Usage Efficiency

To meet the dispensing needs in different scenarios, our Pump & Sprayer products have achieved precise optimization in volume control and atomization effect. The Pump series can achieve quantitative output of 0.1ml-2ml by adjusting the internal piston structure of the pump body and the spring force. Whether it is the essence pump that requires precise dispensing each time in skincare products or the 按压 pump that avoids waste in hand sanitizers, it can ensure a stable and consistent liquid output with each press. This not only reduces the waste of contents but also prevents the use effect from being affected by improper dosage. The Sprayer series adopts a high-pressure atomizing spray head design paired with an anti-dripping valve structure. When spraying, the diameter of the mist droplets is uniformly controlled between 50-100μm, covering a wide area without liquid dripping. It is suitable for scenarios such as household cleaning (such as uniform spraying of glass cleaners), gardening and maintenance (such as precise spraying of foliar fertilizers), and cosmetic setting (such as fine atomization of setting sprays). This makes the spraying process more efficient and worry-free, giving full play to the functional advantages of Pump & Sprayer.

1.3 Durable Materials and Damage-Resistant Design to Extend Service Life

The durability of Pump & Sprayer & Lid products directly affects the long-term user experience. Therefore, we attach great importance to damage resistance in material selection and structural design. All products are made of food-grade PP, PETG, or ABS materials, and some high-end series are even equipped with stainless steel springs and ceramic valve cores. These materials not only meet international safety standards such as FDA and EU 10/2011 but also have excellent corrosion resistance, aging resistance, and impact resistance. When in contact with different types of contents such as acidic cleaners and oil-based skincare products, the materials are not prone to deformation, cracking, or swelling. In daily use, even if the Pump is pressed tens of thousands of times, the Sprayer is frequently exposed to water and sunlight, and the Lid is opened and closed repeatedly, they can still maintain stable performance, avoiding the situation where the product cannot be used normally due to component damage. In addition, our Lid products are also added with anti-scratch coatings and non-slip patterns, which not only improve the durability of the appearance but also enhance the convenience of holding and opening, making Pump & Sprayer & Lid reliable partners for long-term use.

1.4 Diversified Adaptation and Customization to Meet Different Scenario Needs

Different industries and products have significant differences in the specifications, functions, and appearances of Pump & Sprayer & Lid. Relying on a flexible production system and customization capabilities, we provide comprehensive adaptation solutions. In terms of specifications, our Pump is compatible with calibers ranging from 18mm to 40mm, which can match bottle bodies of different capacities; the Sprayer provides various types such as hand-held, press-type, and air-pressure type to meet the different needs of small-range precise spraying and large-area coverage spraying; the Lid has multiple opening methods such as screw-on lids, flip lids, and press lids, which are compatible with containers of different shapes such as circular, square, and special-shaped. In terms of customization, we support adjusting the liquid output of the Pump, the atomization effect of the Sprayer, and the sealing level of the Lid according to customer needs. At the same time, we can provide a variety of colors (such as transparent, white, and custom colors), surface treatments (such as frosted, glossy, and silk-screened logos), and material combinations. This allows Pump & Sprayer & Lid to not only meet functional needs but also be consistent with the overall packaging style of the product, helping brands create a unique visual image and increase product added value.

1.5 Eco-Friendly Design and Compliant Production to Practice Sustainable Concepts

In the current context where the environmental protection trend is becoming increasingly prominent, our Pump & Sprayer & Lid products integrate sustainable concepts throughout the entire process from design to production. In terms of materials, we prioritize the use of recyclable plastic materials such as PP and PETG, and some series use bio-based plastics to reduce reliance on non-renewable resources. In terms of structural design, we simplify the number of components and adopt a modular design, which facilitates disassembly and recycling in the later stage and reduces the difficulty of waste disposal. During the production process, we strictly follow the ISO 14001 environmental management system, optimize the production process to reduce energy consumption and emissions of waste gas and wastewater, ensuring that every Pump & Sprayer & Lid meets mainstream global environmental protection standards. At the same time, our products have passed inspections by authoritative institutions such as SGS and Intertek, and fully comply with compliance requirements such as the EU REACH regulation and the US CPSIA. They do not contain harmful substances such as bisphenol A (BPA) and phthalates. This allows customers to not only meet functional needs when using Pump & Sprayer & Lid but also practice environmental protection responsibilities and convey the brand’s sense of social responsibility.

2. Process Selling Points of Pump & Sprayer & Lid Products

2.1 High-Precision Injection Molding for Stable Product Quality

The production of our Pump, Sprayer, and Lid starts with high-precision injection molding technology, which is the cornerstone of ensuring stable product quality. We use advanced CNC injection molding machines with a positioning accuracy of ±0.01mm, which can accurately replicate the complex structures of each component—whether it is the internal piston of the Pump, the nozzle channel of the Sprayer, or the sealing groove of the Lid. This precision ensures that each batch of Pump & Sprayer & Lid has consistent dimensions, tight fitting between components, and no defects such as burrs or warping. For example, the piston of the Pump, which directly affects the accuracy of liquid output, is molded with a surface roughness of Ra 0.8μm, ensuring smooth movement during pressing and stable liquid output. The Sprayer nozzle, with its micro-channel structure (with a diameter of 0.2mm), is precisely formed through this technology to ensure uniform atomization. This high-precision injection molding technology not only improves the overall performance of Pump & Sprayer & Lid but also lays a solid foundation for their long-term durability.

2.2 Multi-Layer Sealing Process for Optimal Leakage Prevention

Sealing performance is a core selling point of our Pump & Sprayer & Lid, and this is achieved through our multi-layer sealing process. For the Lid, we first embed a food-grade silicone O-ring (with a Shore hardness of 50±5A) into the pre-designed groove of the Lid body. Then, through a heat-press bonding process, the O-ring is tightly combined with the Lid body, eliminating gaps that may cause leakage. For the Pump, we adopt a "double-seal" structure: a primary seal between the pump cylinder and the piston (using nitrile rubber with excellent oil resistance) and a secondary seal at the liquid outlet (using fluororubber with strong corrosion resistance). This multi-layer sealing design ensures that even when Pump & Sprayer & Lid are used with high-viscosity liquids (such as thick lotions) or volatile chemicals, there is no leakage or volatilization. In addition, we conduct a 24-hour pressure test on each batch of Pump & Sprayer & Lid to verify their sealing performance, ensuring that every product meets the highest standards.

2.3 Advanced Surface Treatment to Enhance Aesthetics and Durability

To enhance the aesthetic appeal and functional durability of our Pump & Sprayer & Lid, we apply a variety of advanced surface treatment technologies. For the Lid and Pump body, we offer options such as matte finish, glossy finish, and soft-touch coating. The matte finish is achieved through a sandblasting process, which creates a non-slip and fingerprint-resistant surface that feels comfortable to the touch and adds a high-end look to the product. The glossy finish is obtained through a high-gloss polishing process, which gives Pump & Sprayer & Lid a smooth and reflective surface, enhancing brand visibility when printed with logos. The soft-touch coating, made of polyurethane, provides a velvet-like texture, improving the user's grip experience and making the product stand out in the market. For the Sprayer nozzle, we use an anti-clogging coating (a ceramic-based material) that prevents the accumulation of liquid residues, ensuring smooth spraying even after long-term use. These surface treatment technologies not only make Pump & Sprayer & Lid more attractive but also extend their service life by enhancing scratch resistance and chemical resistance.

2.4 Automated Assembly for High Efficiency and Reliability

The assembly of our Pump & Sprayer & Lid is completed by fully automated assembly lines, which replace manual operations to ensure high efficiency and reliability. The automated assembly line integrates multiple processes, including component feeding, precision fitting, pressure testing, and quality inspection, with a production capacity of up to 500 units per minute for standard models. During the assembly process, sensors and visual inspection systems are used to monitor every step. For example, when assembling the Pump, the system checks whether the spring is installed correctly, whether the piston moves smoothly, and whether the liquid outlet is aligned. For the Sprayer, the system verifies the tightness of the nozzle connection and tests the atomization effect. Any defective products are automatically removed from the production line, ensuring that only qualified Pump & Sprayer & Lid enter the market. This automated assembly not only improves production efficiency and reduces labor costs but also avoids human errors (such as improper component installation) that may affect product performance, making the quality of Pump & Sprayer & Lid more stable and reliable.

2.5 Professional Customization Engineering for Versatile Applications

Recognizing that different industries have unique requirements for Pump & Sprayer & Lid, we provide professional customization engineering services to tailor our products to specific application needs. Our team of engineers works closely with customers to understand their requirements, such as the type of liquid (viscosity, corrosiveness), container specifications (size, shape), and usage scenarios (household, industrial, medical). Based on this information, we optimize the design of each component. For example, for high-viscosity liquids (such as hair conditioners), we increase the diameter of the Pump's liquid inlet and adjust the spring force to ensure smooth liquid output; for medical-grade Sprayers (used in disinfectants), we use USP Class VI-certified materials and add a sterile assembly process to meet medical standards; for large-capacity industrial containers, we design a heavy-duty Lid with a reinforced hinge structure to withstand frequent opening and closing. In addition, we can customize the color, logo, and packaging of Pump & Sprayer & Lid to align with the customer's brand image. This professional customization engineering service ensures that our Pump & Sprayer & Lid not only meet functional needs but also provide additional value for customers in different industries, helping them gain a competitive edge in the market.